Protective Clothing Making Machine

Fully automatic protective gowns body making machine, from material feeding to belt welding, neckline cutting, folding, cuff cutting, shoulder welding, forming and cutting, etc. No need any manual operation and only requires one worker to operate it. At the same time, it is the first in the industry to realize that the nailing function can be turned on selectively to achieve the dual-use of one machine and two products and it replaces most of the traditional manual processes.

- Details

- Specification

- Sample

Protective Clothing Making Machine

1. Automatic feeding, with broken material alarm function, the machine stops working to avoid the waste of raw materials.

2. The unique customized roller cutter has three actions: drag, cut, push and eliminate the phenomenon of material drawing.

3. Full touch screen operation, set the running speed, clearly reflect the working state of the machine, and perfectly realize the human-computer communication.

4. Automatic alarm, automatic fault diagnosis, the cause of the fault is clear at a glance.

5. Tracking of electric eye and edge pulling device makes raw materials go more accurately.

6. All control is realized by software, which is convenient to adjust and upgrade technology, and will never fall behind.

7. Ultrasonic forming welding is more reliable.

8.The whole set of servo control, each servo device can set the speed on the touch screen.

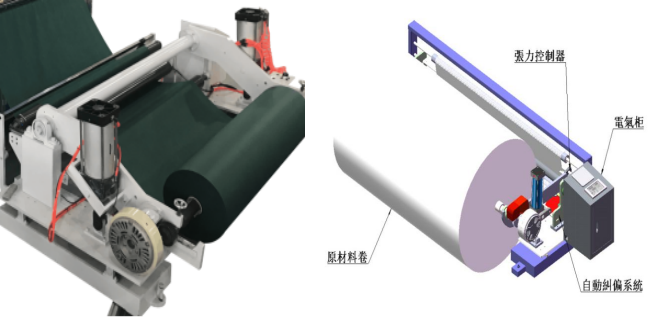

Machine Detail

1.It can directly drive the magnetic powder clutch / brake.

2.The 0 ~ 5V analog voltage can control the frequency converter and servo amplifier.

3.Single or double sensor input, automatic tension zero setting, automatic calibration, etc.

4.Multi line LCD display, Chinese / English menu, simple parameter modification and easy operation.

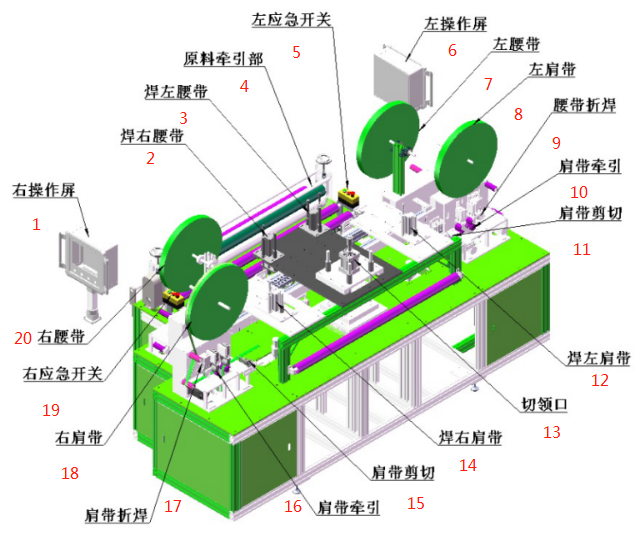

Cut the front neckline and the welding part of tie and belt

1-20:

1. Right operation screen; 2: Welding right belt; 3: Welding left belt; 4: raw material traction; 5: left emergency switch;

6: right operation screen; 7: left belt; 8: left shoulder belt; 9: right shoulder belt folding welding; 10: left shoulder belt traction;

11: left shoulder belt cutting; 12: left shoulder belt welding; 13: collar cutting; 14: right shoulder belt welding;

15: right shoulder belt welding It includes: belt cutting; 16: right shoulder belt traction; 17: right shoulder belt folding and welding;

18: right shoulder belt; 19: right emergency switch; 20: right belt

Folding back part

1-12:

1: Right side pressing wheel; 2: right side positioning piece; 3: right side emergency switch;

4: positioning left and right adjusting hand wheel; 5: positioning lifting adjusting hand wheel;

6: right side top folding; 7: front traction wheel; 8: left side top folding; 9: left side positioning piece;

10: left side emergency switch; 11: left side pressing wheel; 12: rear traction wheel

Welding shoulder cut sleeve hole

1-6:

1: Right sleeve cutting; 2: right adjustment; 3: right shoulder welding;

4: left shoulder welding; 5: left adjustment; 6: left sleeve cutting

Back neckline and finished product cutting department

1-10:

1: Emergency switch; 2: incision adjustment; 3: traction roller adjustment;

4: hob shaft adjustment; 5: traction; 6: traction roller adjustment; 7: finished product slitting section;

8: cutter shaft adjustment; 9: operation screen; 10: finished product conveying

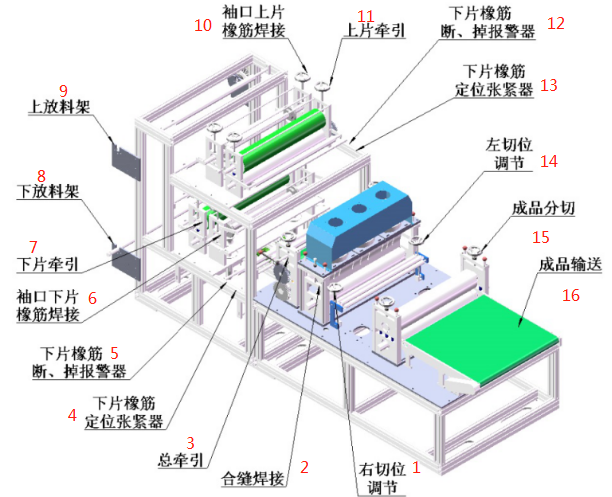

Sleeve production department

1-16:

1: Right side cutter adjustment;2: welding; 3: traction; 4: rubber band positioning;

5: rubber band disconnection alarm; 6: rubber band welding; 7: traction; 8: discharging rack;

9: discharging rack; 10: rubber band welding; 11: traction; 12: rubber band disconnection alarm;

13: rubber band positioning; 14: left side cutter adjustment; 15 finished product cutting; 16: finished product cutting

Machine Packaging Pictures

| Mode | DH-FHF001 |

| Power supply | 35Kg |

| Production speed | 10~15pcs/min |

| Dimension | 8000mm x 2100mm x 2500mm |

| Raw Material Diameter | 500mm – 1000mm |

| Raw Material Width | 1450mm-1600mm |

| Power | 380v |

| Air Pressure | The air pressure is 0.8 MPa and the air consumption is 0.6 m3 / h |

| Raw Material | SMS Nonwoven fabric, SMMS Nonwoven fabric |

| Hs Code | 8449009000 |

| Length Of Cloth | 1.1-1.5meter |

| Bilingualism | Chinese and English |

| Packing Way | Wooden packing |

| Weight | 2500-3000kg |

| Container | 40 high cabinet |