- 6In1 Non Woven Bag Making Machine

- Non Woven Box Bag Making Machine

- D-cut Non Woven Bag Making Machine

- Non Woven Zipper Bag Making Machine

- One-time Forming Nonwoven Bag Making Machine

- Non-woven Fabric Luggage-bag Making Machine

- Non-woven roll to Sheet Cutting and handle Welding Machine

- Nonwoven Fabric Roll To Sheet Cutting Machine

WFB-KT500 One-time Forming Nonwoven Bag Making Machine

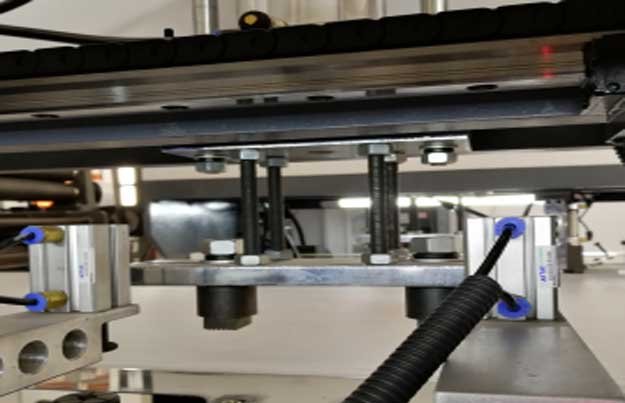

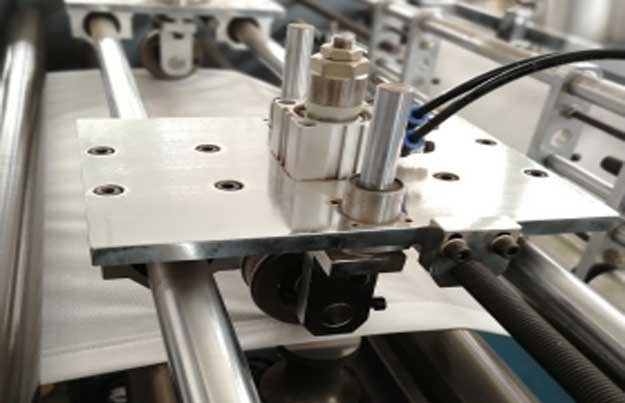

WFB-KT500 is the newest one-time forming nonwoven bag making machine. It use environmentally-friendly non-woven fabric as raw material, combined with optical electrical and ultrasonic bonding technology and the computer PLC control.

- Main Introductions

- Main Parameter

- Samples

WFB-KT500 One-time Forming Nonwoven Bag Making Machine

This machine is the newest full-automatic non-woven bag making machine. It use environmentally-friendly non-woven fabric as raw material, combined with optical electrical and ultrasonic bonding technology and the computer PLC control. At one-time finish on hand, slice, stereo into cylinder, compaction molding. It’s really solves the problem of non-woven handmade box bag high cost and slow efficiency. The finished bag compared to common bag are more beautiful and stronger. It widely used in clothing, footwear, drinks and gift packaging bag production. That’s can save more manual, higher efficiency, creating higher value for customers, allowing you to remain the leading in market competition.

Main advantage and improvement

Transportation

| Model | WFB-KT |

| Size of Bag(height*width*gusset) | 250*250*80mm–450*450*200mm |

| Max.Length of Handle loop | 600mm |

| Total Power | 28KW |

| Production Speed | 20-52pcs/min |

| Weight of Machine | 7000kg |

| Voltage | 220v/380v |

| Overall Dimensions | 9500*2400*2600mm |